|

| Microsite |

| Home Page |

| Company Profile |

| Company News |

| Products Show Room |

| Products News |

| Catalogs & Tech Notes |

| Trade Show Information |

| Web TV |

| Product Alert |

| International Contact |

| Contact Information | ||

|

| Featured Products |

|

Constant Force Springs

Brief:

Constant Torque Spring

Constant force spring is made by winding the steel strip into a coil which exerts a nearly constant retraining force to resist uncoiling. By comparing the differences between constant force spring and traditional wire springs, the advantages will be obtain as following: To exert nearly constant force during entire extension. Short initial deflection, it means that reaching the rated load at short extension. Long extension capability. The product range from 0.03~0.75mm in thickness and 1~50mm in width.

Brief:

Constant torque spring is made by winding steel strip into coil. When springs are counter wound on to output drum from its natural type by a load, force to resist uncoiling will be occurred. However, if load disappears, a constant torque will be output from output drum at the same time. Therefore, it is called constant torque spring. Comparing it with traditional power spring, its advantages are following?To exert nearly constant torque during entire stroke. It has better performance than power spring in more revolution designs. All revolutions are almost useful revolutions. It’s high efficiency. The product range from 0.03~0.75mm in thickness and 1~50mm in width.

|

| Product Categories | ||||||||||||||||

|

|

||||||||||||||||

Copyrights © 2012 Allitwares Corporation All Rights Reserved.

www.allitwares.com is a Division of Allitwares Corporation |

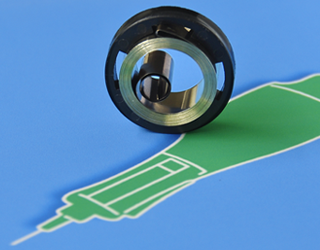

Constant Force Spring | Power Spring Applied to Pen Medicine Injector | Ming Tai Industrial Co., Ltd. |